Clear all your doubts about polypropylene (PP) and polyethylene (PE) plastic and find out what the big difference is between these thermoplastics.

There are many plastic polymers available on the market. There are several names, acronyms, characteristics and indications. Precisely because there is such a wide variety, they also bring many questions. But it is essential that companies that work with these materials know how to differentiate them and know the specifics of each one of them.

It is precisely to help you in this task that we are going to talk about polypropylene and polyethylene plastic. A very common part of our daily lives, PP and PE are obtained from the polymerization of propene and ethylene gas. And precisely because they are synthetic polymers derived from petroleum, these two plastics have somewhat similar properties. However, their differences can also be decisive when choosing which is the best option for your product.

What is PP?

Before talking specifically about the differences between polypropylene and polyethylene plastic, it is important to bring a definition of each of these materials. Polypropylene, also known as PP, is a plastic derived from propylene or propylene. A thermoplastic, it can be modified when subjected to high temperatures, and its melting point is 171ºC.

What is PE?

Polyethylene, known by the acronym PE, is also a thermoplastic. But, its melting point is lower than the other, between 110ºC and 115ºC. With many applications in the plastic industry, it is one of the most used materials today and can be found in 5 variations. Those are:

- HDPE (High Density Polyethylene);

- LDPE (Low Density Polyethylene);

- LLDPE (Linear Low Density Polyethylene);

- UHMWP (Ultra High Molecular Weight Polyethylene);

- PEUBD (Ultra Low Density Polyethylene).

What are their main features?

Despite being quite similar, polypropylene and polyethylene plastics have some specific characteristics that make them more or less suitable for certain uses.

Among the main characteristics of polypropylene are:

- Naturally transparent;

- Balance in thermal, chemical and electrical properties;

- Low resistance to low temperatures;

- High versatility;

- Resistance to common chemicals and solvents;

- Resistance to impacts, UV rays, drops, and corrosion;

- It can be dissolved by phenols and formic acid;

- It can be dyed easily;

- Non-toxic;

- Low cost;

- Easy modeling;

- Good rigidity.

In general, polyethylene is an economical, versatile, flexible, and easy-to-process thermoplastic. But when we talk about its specificities, we must remember that its particularities can change according to the variation of the PE.

LDPE, for example, is low density. This means that it allows the application of thinner and more flexible plastics. In addition, among its main features, the following stand out:

- Impact resistance;

- Good waterproofing;

- Flexibility;

- Ability to form films;

- Chemical resistance;

- Low density.

HDPE, on the other hand, has a higher crystallinity than LDPE, ensuring its fusion at higher temperatures. With this, it can be more transparent than the previous one and also more resistant to heat. However, it is less flexible. In addition to these features, we can highlight:

- Impact resistance;

- Chemical resistance;

- Rigidity;

- Resistance to high temperatures.

What is the difference between polypropylene and polyethylene plastic?

As you can see, polypropylene and polyethylene plastic are very similar. But, they have two big differences: resistance and transparency. In short:

Polypropylene is more transparent and less resistant to sub-zero temperatures, and can even break. Polyethylene, on the other hand, can be subjected to low temperatures without being altered, but its transparency is not as good as PP.

It is for these reasons, for example, that polyethylene is the most suitable for use in packaging materials that need to be frozen. Polypropylene, on the other hand, is the material used to manufacture packaging that is intended to keep the product apparent.

Where are they used?

As we said earlier, it is the characteristics of these thermoplastics that define their usability. And although both are extremely versatile, there are some functions that are better suited for them.

Regarding polypropylene, we can highlight:

- Food packaging;

- Packaging of pharmaceutical and hospital products;

- Plastic bags;

- Plastic films;

- Coating wires and cables;

- Toys;

- Orthoses manufacturing;

- Laboratory furniture;

- Drinking fountain;

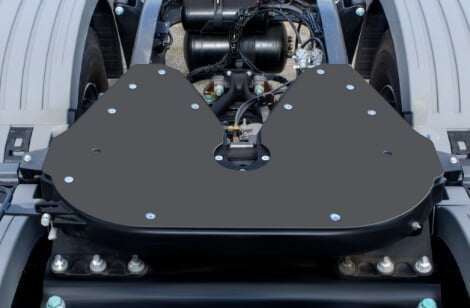

- Agricultural machinery parts;

- Insulation blankets;

- Coating for containers and dump boxes;

- Vehicles;

- Cattle chutes.

Polyethylene is widely used in:

- Bottles of cleaning products;

- Water and sewage pipes;

- Bottles of cosmetics;

- Plastic pallets;

- Chemical packaging;

- Lids, jars, buckets, and bowls;

- Dump boxes coating;

- Truck coating;

- Boats;

- Gas tanks and scrubbers;

- Cutting boards;

- Thermoformed trays.

Now that you know the differences and the main characteristics of polypropylene and polyethylene plastic, get to know Lamiex products. Specialists in PP and PE laminate sheets, we serve from the food sector, to mining, water treatment, automotive and much more.

Do not waste time

Check the Lamiex product catalog.